Series and Parallel Configuration of Lithium Battery

This article talks about the different configurations of Lithium-ion Battery in Series and Parallel configurations, and its effects on their performance.

Do you know how Lithium-ion battery packs form? The Lithium-ion battery pack is the combination of series and parallel connections of the cell. In this blog batteries in series vs parallel we are talking about Series and Parallel Configuration of Lithium Battery. By configuring these several cells in series we get desired operating voltage. Also the Parallel connection of these cells increase the capacity which directly increase the total ampere-hour (Ah) rating of the battery pack.

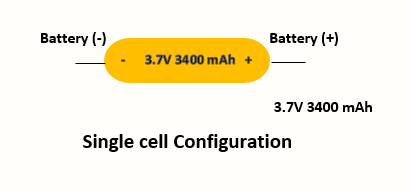

Single cell configuration

The single-cell configuration is the simplest battery pack. Typical these configuration are available in mobile phones and tablets with one 3.7V Lithium-ion cell. Other uses of a single cell are wall clocks, which typically use a 1.5V alkaline cell, wristwatches and memory backup, most of which are very low power applications. The below image shows the single cell configuration of Lithium-ion cell.

The nominal cell voltage for a nickel-based battery is 1.2V. for alkaline it is 1.5V; silver-oxide is 1.6V and lead acid is 2.0V. Primary lithium batteries range between 3.0V and 3.9V. Li-ion is 3.7V. Li-phosphate is 3.2V and Li-titanate is 2.4V. Li-manganese and other lithium-based systems often use cell voltages of 3.7V and higher.

The nominal cell voltage for a nickel-based battery is 1.2V. for alkaline it is 1.5V; silver-oxide is 1.6V and lead acid is 2.0V. Primary lithium batteries range between 3.0V and 3.9V. Li-ion is 3.7V. Li-phosphate is 3.2V and Li-titanate is 2.4V. Li-manganese and other lithium-based systems often use cell voltages of 3.7V and higher.

MUST READ BLOG POSTS ON BATTERY

- Working of Lithium-ion battery

- Lithium-ion battery vs Lithium-polymer battery

- How to Choose Lithium Polymer Battery for your RC Drone

- Introduction to Lithium iron phosphate battery

There are different types of batteries in series vs parallel pack formation and they are explaning as follow,

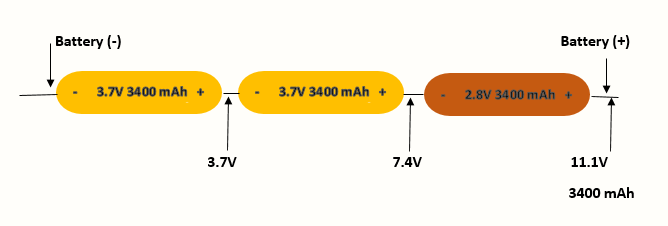

Series configuration

Some of the portable equipment requires higher voltage battery packs. so in thi case the voltage can increase by connecting these cell in series. The below figure shows a battery pack of three 3.7V Lithium-ion cells. These cells are connected in series now this 3S or 3 cell battery pack which produce 11.1 V in nominal mode.

Similarly, six-cell lead acid string with 2 V/cell will generate 12 V and four alkaline with 1.5 V/cell will produce 6 V. According with the required voltage for your application, you can connect the number of cells in series.

If one of the cell of the battery pack gets discharged or damaged then the battery pack shows the notification. This notification gets due to the protection board used in it. The below image illustrates a battery pack in which “cell 3” produces only 2.8V instead of the full nominal 3.7V.

With depressed operating voltage, this battery reaches the end-of-discharge point earlier than a normal pack. The voltage collapses and the device turns off with a “Low Battery” message. At this point you have to charge your battery pack with suitable charger.

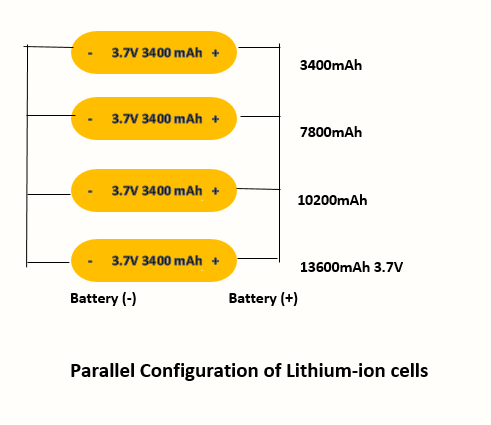

Parallel Configuration

If the applications require the higher current capacity battery and larger cells are not available then by using the parallel configuration of these cells, the current capacity can increase. Most of the battery chemistries allow parallel configurations with little side effect. The below image shows the parallel configuration of four cells. The nominal voltage of the illustrated pack remains at 3.7V, but the capacity (Ah) and runtime are increased.

A cell that develops high resistance in a parallel circuit than in a series configuration. But in the parallel configuration, a failing or faulty cell will reduce the total load capability. On the other hand, an electrical short is more serious as the faulty cell drains energy from the other cells, it causes a fire hazard. Large packs often include a fuse that disconnects the failing cell from the parallel circuit if it were to short.

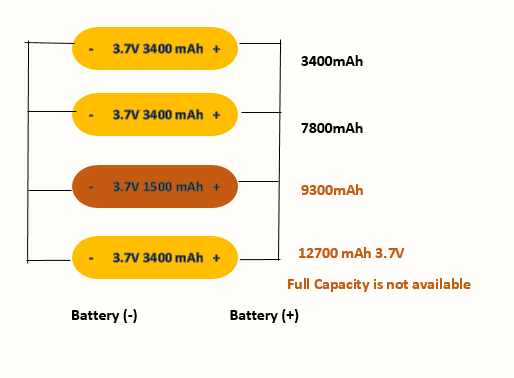

Below image shows the parallel configuration with one faulty cell. In that, the capacity of third cell is 1500 mah. Weak cell will not affect the voltage but provide a low runtime due to reduced capacity.

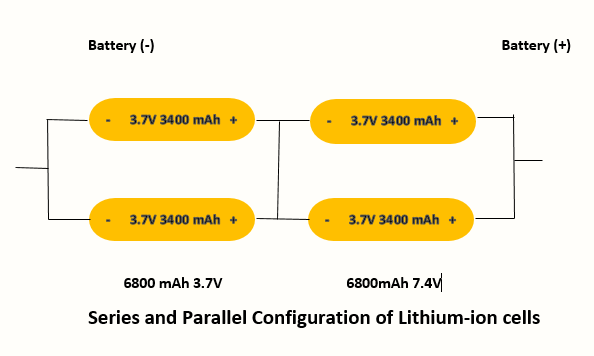

Series and parallel configuration

Using the series and parallel configuration, you can design the more voltage and higher capacity battery pack with a standard cell size. The below figure shows the configuration of 2S2P configuration of the 18650 lithium-ion cells. Here, 2 cells connect in series and 2 cells are in parallel. The total power is the sum of voltage times current. A 3.7V (nominal) cell multiplied by 3400mAh produces 12.58Wh.

Four 18650 Lithium-ion cells of 3400 mAh can connect in series and parallel as shown to get 7.2 V nominal and 12.58 Wh. The slim cell allows flexible pack design but every battery pack requires the battery protection circuit. Generally integrated circuits (ICs) for various cell combinations are available in the market. Larger packs need custom circuits. This larger battery packs use in e-bike batteries, hybrid cars and the Tesla Model.

Safety devices in Series and Parallel configuration

The positive Temperature Coefficient Switches (PTC) and Charge Interrupt Devices (CID) protect the battery from overcurrent and excessive pressure. The PTC and CID work as expected to switch of the cell on excessive current and internal cell pressure, the shutdown occurs in cascade format. While some cells may go offline early, the load current causes excess current on the remaining cells. Such overload condition could lead to a thermal runaway before the remaining safety devices activate.

We at Robu.in hope that you found this artical batteries in series vs parallel interesting and that you will come back for more of our educational blogs.