Design Considerations for 3D printing – Things To Know in 2021

In this article, we will understand the major considerations that every 3D designer should follow when designing a 3D object.

Design Considerations for 3D printing: Nowadays, the 3D printing industry is so popular in the object manufacturing industry. In 3D printing, we first design a 3D model of the object and then pass that designed 3D model to the 3D printing machine. Once the 3D model is received, the machine starts printing the object.

But what if the 3D model has errors? If there are flaws in the 3D model, then printing such a model would be of no use. Therefore, to avoid these types of issues, we have to follow some 3D printing guidelines.

In this blog, I have explained all the considerations that will help you in the design of the most accurate and reliable 3D print. Hope you like this blog.

Before continuing this discussion, I presume that you know "what is 3D printing?", If not, you can check our following blogs.

- What Is 3D Printing? Types OF 3D Printing.

- Types of 3D Printers: Complete Guide – SLA, DMLS, FDM, SLS

Digital Vs Physical

As discussed in those blogs, we design a 3D object. This means that we first create a 3D model of the object (digital data) and then pass that 3D model to the 3D printing machine.

After receiving the data, the 3D printing machine converts that data into layers and starts printing the object.

But do you know one thing? We can design almost anything using 3D printing software but can we print anything?

Was that a bouncer? I know what you are thinking. The above sentence is correct. We can design almost everything. When designing we do not think about physics, gravity, and other physics-related things.

But when converting that 3D model into a real 3D printed object, we have to think about all those physics-related words. Otherwise, our object would not look as good as we wanted it to.

So always keep in mind that whatever object you design, has to follow all the laws related to physics.

Some of you may now be wondering if we need to read a physics book to design a 3D object?

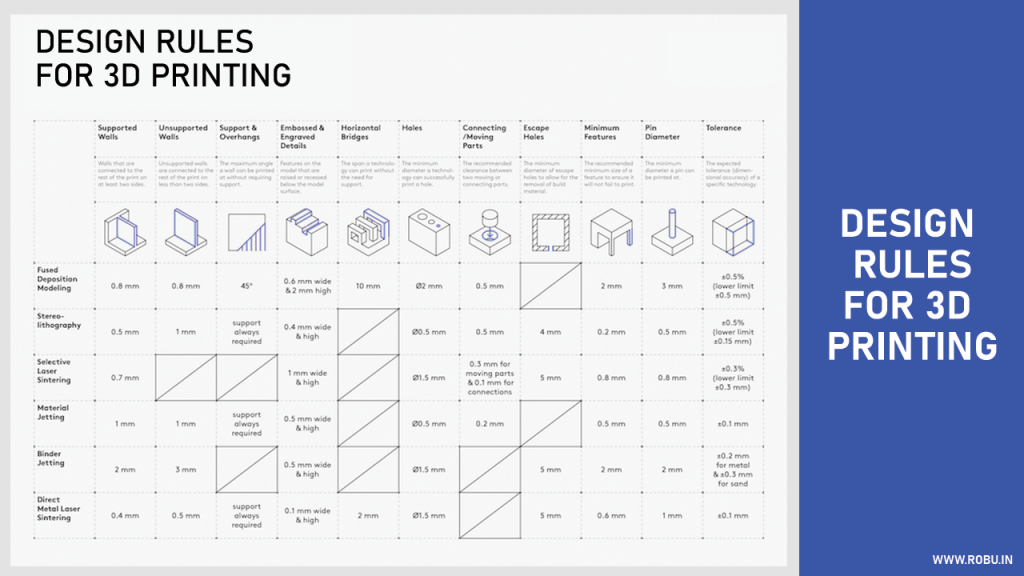

The answer is no. You just have to follow some rules given below. And keep the following infographics with you when designing 3D objects. This will help you to design the best 3D print.

Basics Considerations We Need To Follow While Designing An 3D Model

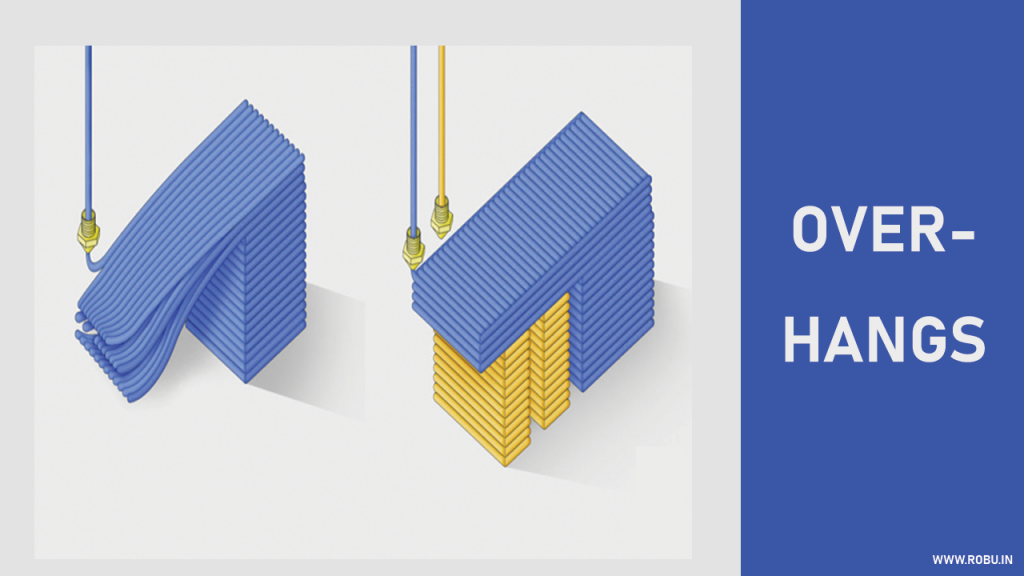

1) Overhangs in 3D Printing:

Many times, when designing a 3D object, the parts of the object move outward from the previous layer. In such cases, we are sometimes required to use support material and, in some cases, we do not. The extended part hangs in the air and according to the laws of physics, we cannot print the object in the air.

Using support materials may be the best option, but not the eco-budget option. According to the rules of 3D printing, any 3D printer can design objects with an overhang angle of up to 45 degrees without dropping the object.

Having said this, it does not mean that it is a silver bullet point, yet you have to make some changes to prevent your object from falling.

The following things you can do to avoid overhang issues.

- Make use of high-speed Fans. (So that the objects cool down fast)

- Reduce the speed of printing.

- Reduce the Hight of the layer.

- Increase the slicing rate of the object.

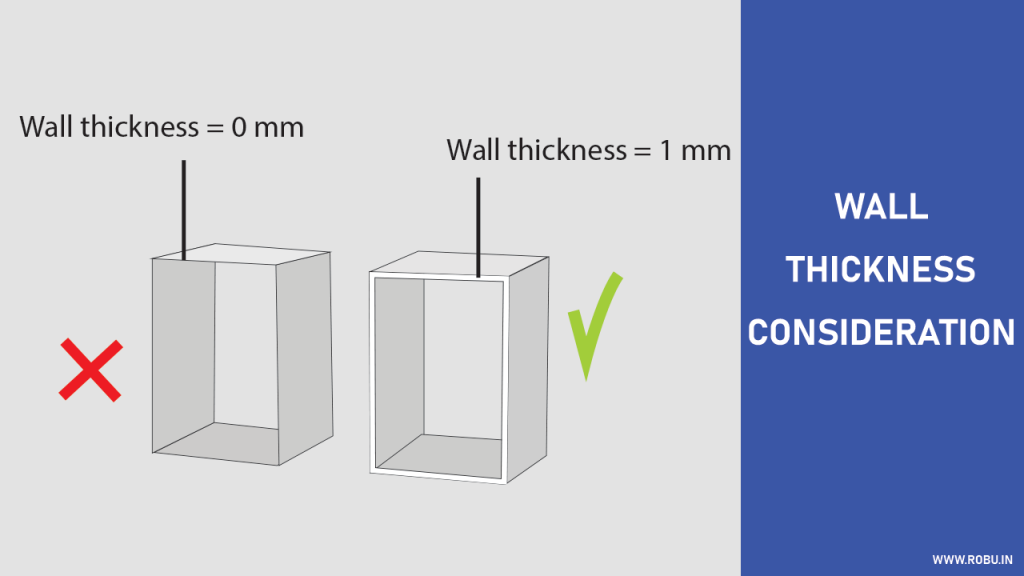

2) Wall thickness Consideration in 3D Printing:

This is the second consideration in 3D printing we should keep in mind when designing a 3D object.

Why is it so important? Let me tell you. As we know the 3D printing machine prints the object layer by layer. As a result, if we are designing the object that the wall thickness of the part of the 3D object is too small, then that part will not be attached to the object, that part will come out easily.

However, if that part does not come out, then in the post-design process, the object has to undergo a water jet process, where part of the wall of small thickness will easily break at this level.

So, always add thickness to your model to avoid such a thing. The part that has a wall thickness of more than 0.8 mm can be printed without any damage.

3) Wrapping Consideration in 3D Printing

This is the third consideration of the 3D printing process. Wrapping refers to a physical change in a 3D printing object. You must be wondering what physical changes I am talking about here? Before answering that question, let me tell you some basics.

When the machine deposits a layer of filament on the build platform, this layer is in an un-solid state and starts to shrink as it cools. This process continues until the temperature of the material drops below the temperature of the build platform. And as a result, the base of objects starts to wrap up.

Such issues can be avoided by using the following methods:

- Make use of heated build-platform

- Adjust the Level of the build-platform correctly

- Adjust the setting of the fan properly.

- Apply Adhesive on the build platform

4) Level Of Details Consideration in 3D Printing

As the name implies, considering this idea means adding some additional detail to the 3D object design. If we are designing an object, we should know the details about the maximum width of the material and the thickness of the object. According to those descriptions, we can design the required item.

However, these details also affect the speed and cost of the item. So deciding whether the small details are important to your model is an important task.

Through this part of the blog, we have learned the basic rules that we need to follow when designing 3D models. In the next part of the blog, we will know the rules that need to be considered when using the FDM process.

How To Design Parts For FDM 3D Printing? Considerations in FDM 3D Printing

Before starting to discuss this section, I understand that you have an adequate understanding of the FDM 3D printing process. If not, you can refer to the following blog.

Coming back to our discussion, the FDM 3D printing process is the most favourable and inexpensive 3D printing process. In this 3D printing process, the material is first melted and then deposited on the build platform.

You may consider this process an easy process but this process has some limitations and constraints. We will discuss those limitations and constraints in detail in the section below.

1) Bridging

Bridging occurs when we try to print layers on two different structures of an object. When we print the layers on those two structures of the object, holes will be formed on the initial layers. We can reduce the issue by reducing the distance between two objects, but what if that distance is not reducible?

In that case, you can use the following methods to avoid this issue.

- Increase Cooling Speed

If you are designing a bridge and you want it to be a perfect print then increase the fan speed. By doing this, the process of freezing of material will accelerate and stop the formation of holes.

- Reduce the flow of the material

For a successive bridge, the material has to be deposited in a sufficient manner by a 3D printing machine and if the flow of material is fast, it will take longer to set and this will form holes in the layers.

Therefore, if we control the flow of material through the nozzle, we will be able to print the correct bridge without holes on the layers.

- Adjust the Temperature of the nozzle

If the nozzle temperature is too high and the maximum flow of material is allowed through the nozzle, the printed layer will take longer to set, resulting in holes on the initial layers of the bridge.

So, to avoid this, we have to keep the nozzle temperature as low as possible. To identify the exact value of temperature, you may have to print some test samples.

- Adding Support Material

This is another method we can use to avoid the issues we face when combining two different structures of the object.

Once the design of the bridge is complete, we can extract that support material.

2) Overhangs

As discussed in the previous section, overhang occurs when the new layer extends beyond the previous layer and no support material is supplied.

According to 3D printing rules, any FDM 3D printer can print overhangs up to 45 degrees without any damage or without any change in the physical structure of the object.

Issues caused by overhangs can be mitigated by using a high-speed fan or by using support materials

3) Corners

As in FDM, the nozzle is spherical in shape, the edges/corners that will be designed will have a circular shape. So how is it possible to print sharp edges/corners?

For sharp edges/corners, we generally prefer the SLA 3D printing process but FDM can also be used for the same application.

But to do this, we have to slow down the process of printing the object.

How To Design Parts For SLA 3D Printing? Consideration in SLA 3D Printing

In previous blogs, we talked about how SLA 3D printing works. SLA 3D printing machines use lasers to cure the resin.

In this section of this blog, we will talk about some of the most important considerations, which we should do while designing SLA 3D printing objects.

1) Wall Thickness

If we talk about walls, there are two types of walls. 1) supported walls and 2) unsupported walls.

Talking about supporting walls, these are walls that join two different structures of the object that is to be printed. If the thickness of such walls is less than 0.4 mm then such walls can come out easily. Therefore, the thickness of such walls should be more than 0.4 mm to avoid such issues.

It was about the supporting walls, now what about the unsupported walls? Unsupported walls are walls that are attached to the structure of the base object but no other part of those walls will be attached to any part of the object. The thickness of such walls should be more than 0.6 mm otherwise it will be easily separated from the structure of such 3D objects.

2) Overhangs

We have talked about this consideration in the previous part of this blog. In SLA 3D printing, the overhang angle should not exceed 19 degrees.

3) Holes

Sometimes we need to put some holes on a 3D printing object. Those holes are used to insert mounting screws or can be used as insertion slots.

The diameter of such holes should be more than 0.5 mm otherwise those holes will not be printed.

4) Embossed Description

We may have seen names on 3D printing objects many times. In SLA the minimum height printing of such things should be more than 0.1 mm.

So, this was about the most important considerations that we should do while designing SLA 3D printing objects. If you have any doubt about this section, please let me know in the comment section.

How To Design Parts For DMLS 3D Printing? Consideration in DMLS 3D Printing

As discussed in our previous blog, DMLS 3D printing is a type of metal printing.

DMLS metal 3D printing is one of the most demanding 3D printing processes nowadays. In this section of this blog, we will talk about the most important considerations that we should follow when using the DMLS 3D printing process.

1) Wall Thickness

The thickness of the object wall should be greater than 0.4 mm according to the DMLS 3D printing standard.

Small thickness wall printing is also possible, but this will depend on the type of material and the parameters of the 3D printing machine.

2) Pin Diameter

In DMLS, the pin diameter must be greater than 1 mm. small pin diameter is possible but again, this will depend on the type of material being used and the type of 3D printer being used.

3) Overhang

The maximum permissible overhang angle for DMLS 3D printing is 45 degrees and it should not exceed this angle.

4) Hole Diameter

The DMLS 3D printer can easily print 0.3 mm diameter holes without any support.

These are the most useful considerations of DMLS 3D printing. I believe that this section has dispelled your doubts about the considerations of DMLS. If you have any doubt, please let me know in the comments section.

Conclusion

In this blog, we have learned the basic rules of 3D printing. I am confident that these rules will help you to design the best quality 3D-printed objects. If you have any doubt, please let us know in the comment section.

Also, do you know? You can use our affordable online 3D printing service to print 3D models and get them delivered to your doorstep in as little as two days. We offer instant quotations. Click Here to explore more!