What Is 3D Printing? – Working, Types, Software, Process of Printing

3D printing technology is a widely used technique. It creates objects by printing layers in a predefined manner.

Hello and welcome. As you are here, you may be interested in knowing how the 3D printing process works and how many types of 3D printing processes are available in the market.

If this is your motto then you are at the right place. 3D printing is the process of creating a three-dimensional solid object from digital data.

Today 3D printing machines can be seen not only making small objects like toys but also designing things that can be used against the battle of Covid.

In 3D printing, the first step is to convert the real image into digital data and there are lots of 3D printing software available in the market to do so. Using that 3D printing software, we can create digital data of the real object.

The Digital data which has been created by the 3D printing software is known as the 3D model.

This 3D model is then given to a 3D printing machine. After getting the 3D model of the object, the 3D printer starts designing the object.

3D Printing Technology

Before we talk about 3D printing technology, there are a lot of manufacturing processes available in the market but here I am only sharing the main four manufacturing technologies that are most used to design products.

1. Subtractive Manufacturing Process

The Subtractive manufacturing process is one of the oldest methods we have used for centuries. Ajanta caves are the best example of this process. Couldn’t understand what I said? Let me explain.

Ajanta caves are the oldest man-made architecture. According to Wikipedia, those caves are engraved on a wall.

The engraving process is nothing but the removal of the unwanted part from the original part and is known as the subtractive object manufacturing process.

2. Forming Manufacturing Process

It is the second most popular and oldest method of object designing. Have you seen the process of making clay pottery? Some of you may know how clay pottery is made.

In the clay pottery designing process, the craftsman creates a mixture of sand and pressing the mixture gives the object the required shape, the image below will clarify your doubts.

Creating an object by creating pressure is known as the forming process. In this process, the material is pressed and given the required size.

3. Casting Manufacturing Process

In the casting object manufacturing process, The molds are created for the object being designed and then the material used to design the object is melted and poured into those molds and kept for cooling.

Once the material cools, the mold is removed and we get the required size item.

The process in which the mold is used to design the object is known as the casting manufacturing process.

4. Additive Manufacturing process.

This commodity manufacturing process by adding materials is the latest technology that is being adopted by many companies.

The 3D printer is the most appropriate example of this manufacturing process.

In this process, the material being used to design the object is melted, dispersed, liquefied and poured layer by layer into the manufacturing stage and repeats this process until the product is manufactured.

The 3D printing technique is known as Additive Manufacturing (AM). It creates objects by adding layers upon layers.

Using 3D printing technology, you can easily design complex objects. Not only this, but this technique also saves a lot of material.

However, some materials are also wasted in the 3D printing process. But if the 3D model is designed properly, the material wastage can be prevented.

In this section we learned the different types of object manufacturing techniques that are available in the market, In the next section of this blog, we will learn the working of 3D printing.

How Does 3D Printing Work?

1. 3D Model

Any 3D printing process begins with a 3D model. These 3D models can be created using a computer-aided design (CAD) software package. Below I have mentioned some names of software that you can use to design a 3D model.

- Fusion 360

- Autodesk Inventor

- SolidWorks

- Catia

Which is the best 3D printing software for 3D printing?

The above mentioned are 3D printing software that are used for designing the 3D model but which one to choose this question might be in your mind.

Fusion 360

Fusion 360 is one of the low-cost 3D-model designing software. Using this software, flat surface objects can be easily designed.

But as it is low-cost 3D software, more complex objects cannot be designed using this software.

Solid Works And Autodesk Inventor

These two software rival each other. Using this two software, we can design complex 3D models so easily.

If we compare the scores of both software with accuracy, both software scores are the same.

But if we examine community support, then SolidWorks software has more community support than Inventor and so if you are new, you should start learning SolidWorks software. As you get online support easily and your work does not stop.

Catia

It is the most compatible 3D model designing software. This software is a bit expensive and I would recommend this software only to professional people.

Being the expensive software available in the market, this model provides you with a number of useful features and creating bug-free STL files is one of those features.

If you are new and if you do not want to go into designing 3D printing models then you can use 3D printing model websites.

There are a lot of websites in the market that accept user input and design and sell STL file of user inputted files.

You can make use of those websites if you are new.

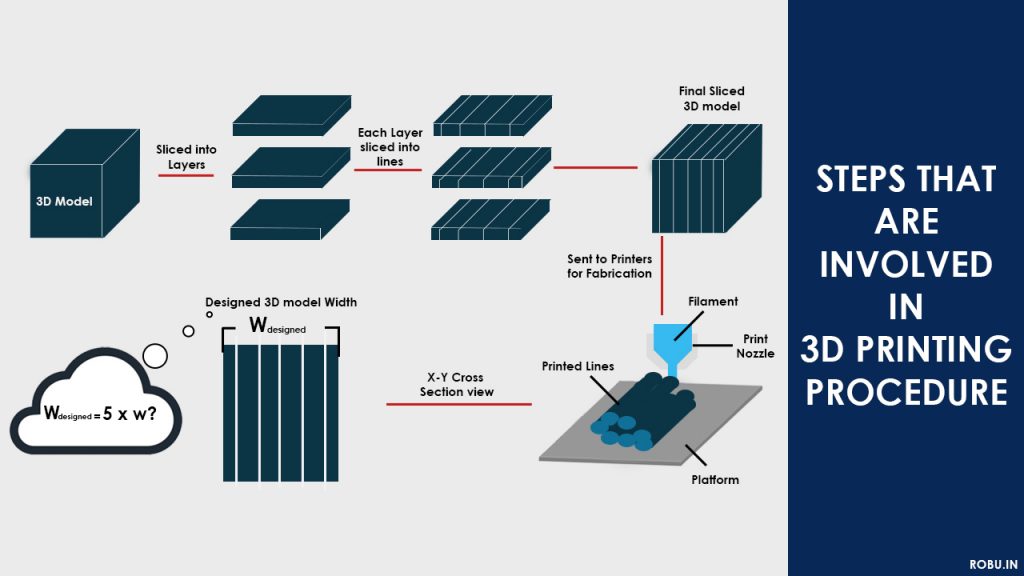

2. Slicing Process

To make the object 3D machine-understandable, we will have to use the slicing process. The slicing process is nothing but a process of slicing the 3D model in layers. These sliced layers then send to the head of the machine.

The following software's can be used for the completion of the slicing process.

These slicing tools also add support-column, where needed. The use of that support-column is they provide supports the sculpture of the object.

Why we need support-column? This question may be in your mind. The object that has been created using 3D printers cannot stand in the air as the material that is being used will be in melted form. So, we need support columns to support the object

3. Transferring the data to 3D printing machines.

After the slicing process is done, the data is then sent to the 3D printer machine. These printer machines then begin to print the object layer by layer.

Overview: Steps That Are Involved In 3D Printing Procedure

There are so many steps that are involved in the 3D printing procedure and each of them has its own importance. if we don’t use them in the right manner, we may not design the product correctly.

Here are the steps that are involved in the 3D printing designing process.

- Designing the 3D model using any CAD software.

- After designing the 3D model, the data file of the 3D model is then converted into standard tessellation language (STL) format.

- After this that STL file is then transferred to the computer that controls the 3D printer.

- Once the data is transferred to the 3D printing machine, the machine will start printing the object layer by layer. Now your job is to wait for the process to finish and monitor the process.

- After this, the next step is removing the extra material that has been created by the 3D printer while building the object.

3D Printing Industry

As technology is advancing, we are discontinuing the use of technologies that are time-consuming and not so useful. The subtractive manufacturing process is also one of those technologies.

To make the business more profitable, there are many industries that have adopted 3D printing technology for object manufacturing. I have listed some of them below.

- Eyeware industry

- Footwear industry

- Drone Designs

- Electronics Industry

- Jewellery

3D printing technology is being used in almost every industry you think of. Up to this point, we have understood the use of 3D printing technology, in the next part we will discuss the types of 3D printing technology that are available in the market.

Types of 3D printing Technology:

According to the American Society for Testing and Materials (ASTM), there are a total of 7 sets of standards that classify the additive manufacturing process into 7 categories. Those 7 categories are as follows:

- Vat Photopolymerization

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Material Jetting

- Binder Jetting

- Material Extrusion

- Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Powder Bed Fusion (Polymers)

- Selective Laser Sintering (SLS)

- Powder Bed Fusion (Polymers)

The above processes are standard processes for 3D printing. These processes differ from each other and have their own value. I have explained some of them below. If you want to know about the rest of the procedures, please let me know in the comments section.

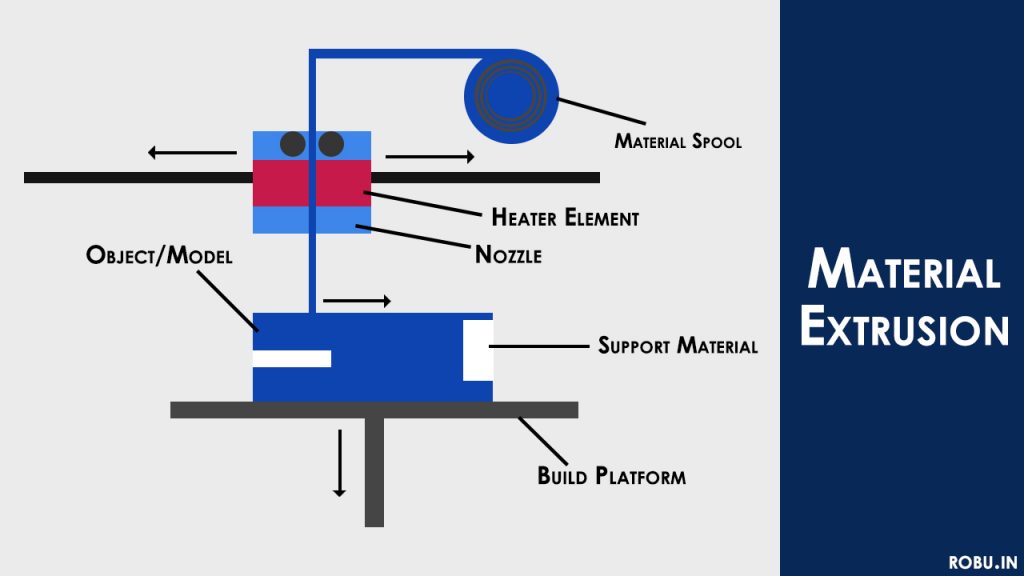

Material Extrusion

The material extrusion technique is a very popular technique nowadays. In this technique, the plastic material or filament is inserted into the machine through a nozzle, where the filament is heated using a heater and then deposited layer upon layer on the hotbed.

The temperature of the heater is controlled by a thermistor. The thermistor is connected to the heater which measures the temperature of the heater and gives an input signal to the controller.

Fused Deposition Modeling (FDM)

FDM is a subcategory of material extrusion technology. Nowadays you can see every technology is using this technology for their business needs. This technology is very fast and so accurate.

The steps are included in the FDM process are as follows:

- The proper filament is first selected and loaded into the printer. After this heater is turned on. Once the temperature of the heater reaches the desired temperature the filament is fed to the extruder head.

- Different sizes of extruders are available in the market. The selection of these extruders depends on the particular application and type of machine used. This extruder is connected to a 3-axis system that allows it to move in the x, y and z directions.

- With the help of this 3-axis system, the melted filament is deposited layer by layer in programmed locations, where it cools and solidifies.

- The process of applying melted filament is repeated until the complete object has been created.

Conclusion:

In this blog, we learned what is a 3D printing technology and what is the importance of 3D printing technology. In our next blog, we will understand the most commonly used types of 3D printing technology. If you have any doubt, please let us know in the comments section.

Also, do you know? You can use our affordable online 3D printing service to print 3D models and get them delivered to your doorstep in as little as two days. We offer instant quotations. Click Here to explore more!