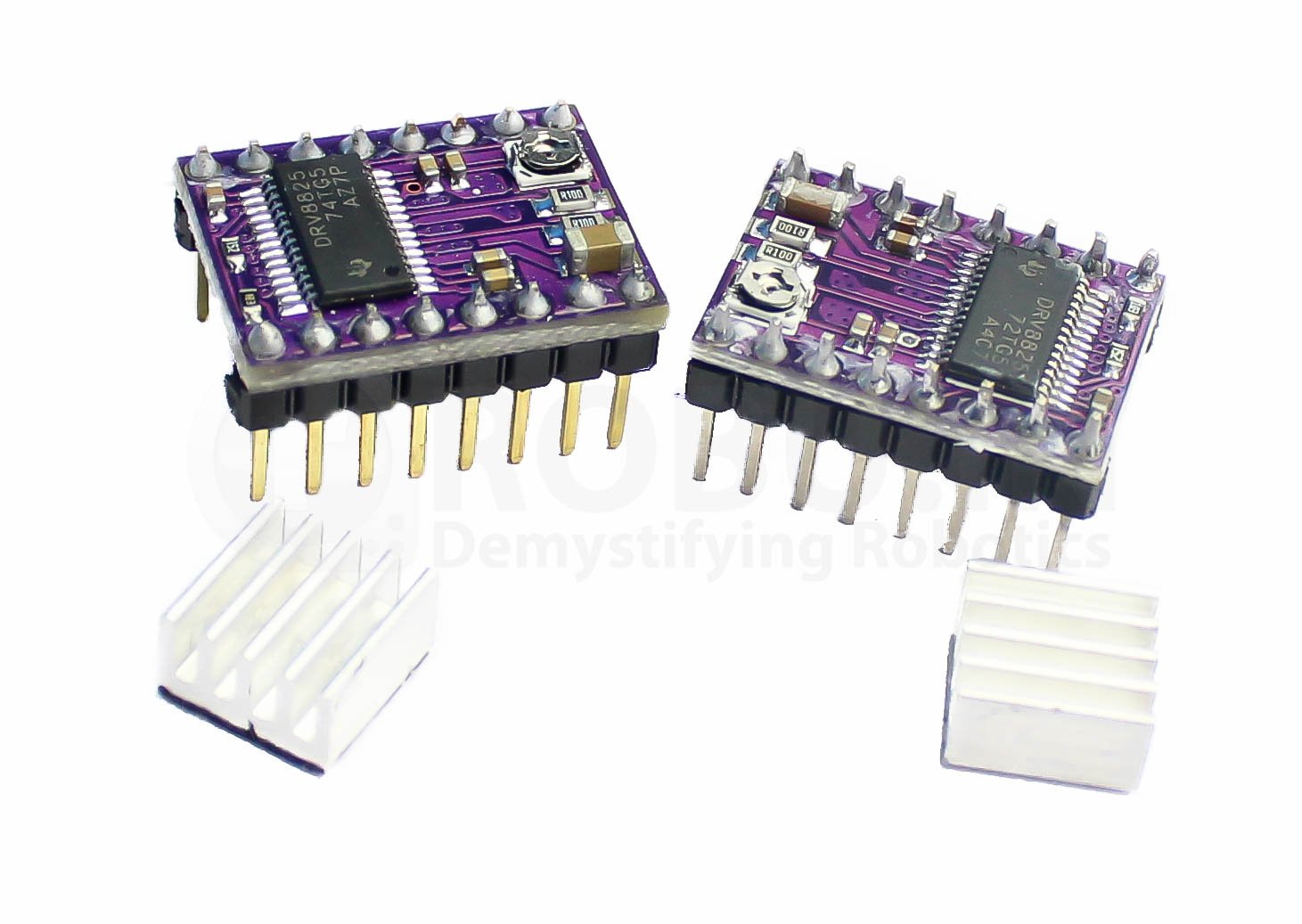

The DRV8825 Stepper Motor Driver with Aluminum Heat Sink is a breakout board for TI’s DRV8825 microstepping bipolar stepper motor driver.

The module has a pinout and interface that are nearly identical to those of the A4988 stepper motor driver carriers, so it can be used as a higher-performance drop-in replacement for those boards in many applications.

The DRV8825 features adjustable current limiting, overcurrent, and overtemperature protection, and six microstep resolutions (down to 1/32-step). It operates from 8.2 – 45 V and can deliver up to approximately 1.5 A per phase without a heat sink or forced air flow (rated for up to 2.2 A per coil with sufficient additional cooling).

Note: We are supplying two DRV8825 Drivers as DRV8825 Stepper Motor Driver with Aluminum Heat Sink- Good Quality and DRV8825 Stepper Motor Driver with Aluminum Heat Sink- Normal Quality. The difference between them is, the good quality DRV8825 has more number of PCB layers and it features the connecting pins which are of gold plated as compared to other. (refer to above image)

Using the Driver

Features :

- Microstep resolutions: full, 1/2, 1/4, 1/8, 1/16, and 1/32.

- Simple step and direction control interface

- Six different step resolutions: full-step, half-step, 1/4-step, 1/8-step, 1/16-step, and 1/32-step

- Adjustable current control lets you set the maximum current output with a potentiometer. Hence lets you use voltages above your stepper motor’s rated voltage to achieve higher step rates

- Intelligent chopping control that automatically selects the correct current decay mode (fast decay or slow decay)

- 45 V maximum supply voltage

- Built-in regulator (no external logic voltage supply needed)

- Can interface directly with 3.3 V and 5 V systems

- Over-temperature thermal shutdown, over-current shutdown, and under-voltage lockout

- Short-to-ground and shorted-load protection

- 4-layer, 2 oz copper PCB for improved heat dissipation

- Exposed solderable ground pad below the driver IC on the bottom of the PCB

Package Includes :

1 x DRV8825 Stepper Motor Driver with Aluminum Heat Sink- Good Quality.

NaveenR (verified owner) –

These drivers though affordable are extremely fragile. The trimpot on mine broke during the current adjustment! so it became useless now. I would suggest Ya’ll go for branded drivers.

NaveenR –

Chaitanya (verified owner) –

working fine without any issues.

Chaitanya –

owais mech (verified owner) –

it is good at this price but you alo must have to be lucky i brought 2 but 1 is not working but thanks to support team they are very good people.

owais mech –

souvikdey.official (verified owner) –

Amazing product works like a charm and delivery was very fast and efficient

souvikdey.official –

nharishankar (verified owner) –

I’ve been using this for stepper motor for more than a month and my Robot vehicle is working amazing. Don’t buy this anywhere else, I’ve had enough trouble buying it on other places.

nharishankar –

gurpreet80singh –

not useful, burnt within a second.

gurpreet80singh –

ANKIT SHARMA (verified owner) –

This is a fantastic piece of brilliant engineering,very vertalile up to 24 volts ,no any issue of failure like l293d with 24 volts.

ANKIT SHARMA –

mayurkumarchauhan19@gmail.com –

Good , awesome working

mayurkumarchauhan19@gmail.com –

Ravindra V (verified owner) –

This is an excellent stepper driver for 3d printer, CNC machine. I got the delivery in a days time.

As usual Robu excels in delivery and quality,

Ravindra V –

Amul Agrawal –

?Good product and good delivery in time

Amul Agrawal –