3D Printer Filament Types

In this guide, we look at the 3D printer filament types while also covering their uses along with pros and cons for each type.

One of the most important parts of 3D printing is to use the right kind of material for the job in hand. In this guide, we look at the 3D printer filament types. We will also cover their uses along with pros and cons for each type. This will help you to make better informed decisions when buying your 3D printer filaments.

What is 3D Filament?

3D filaments are special types of plastics called thermoplastics. The thermoplastics become flexible if heated to the right temperature. It allows the printer to sculpt the filament to create your shapes before it cools down.

Here is the video explaining some of the 3D printer filaments.

Types of 3D Printer Filament

From the beginning, an ABS and PLA type filaments are post popular filaments. In this blog, We will discuss all types of filaments. Also, all 3D printers can't utilize both ABS and PLA filaments. So you need to know your 3D printer capabilities as well as the abilities of the 3D filaments.

Below are the 3D Printer Filament Types that we are going to cover in this blog.

- ABS Filament

- PLA Filament

- PET Filament

- PETT Filament

- Nylon Filament

- PVA Filament

- Sandstone Filament

- Wood Filament

- Metal Filament

- HIPS Filament

- Magnetic Iron Filament

- Conductive Filament

- Carbon Fiber Filament

- TPE Filament

- Glow in the Dark Filament

- Amphora Filament

1. ABS 3D Filament

ABS is popular for it’s toughness and impact-resistant properties. This strength and moderate flexibility that makes it such a great choice for printing in 3D.

ABS print temperature range: 210°C – 250°C (high)

Applications of an ABS 3D Filament

ABS filament is a great choice for printing plastic automotive parts, moving parts, musical instruments, kitchen appliances, electronic housings, and various toys, like LEGO. It has other applications too, aside from 3D printing. For example, traditional manufacturers use ABS to make plastic wrap, water bottles, and cups, to name a few uses. Despite its popularity for 3D printing, ABS is not the best filament for most home users. This is because it has a high melting point that needs to print on a heated surface, or bed. A heated printer bed is not something a lot of budget-range 3D printers come equipped with. Printing with ABS also produces unpleasant fumes that can irritate some people. Needless to say, good ventilation is essential. These things combined make ABS a material favored more by professionals than amateur users.

Pros and cons of an ABS 3D Filament

Pros

- A durable, strong 3D filament

- Quite flexible and lightweight

- Cheapest thermoplastic available at the time of writing

- Most favored material among professional 3D printers and keen armatures

Cons

- ABS is petroleum-based, making it a non-biodegradable material

- Needs a high temperature to reach its melting point

- Creates unpleasant fumes, most notable in poorly ventilated spaces

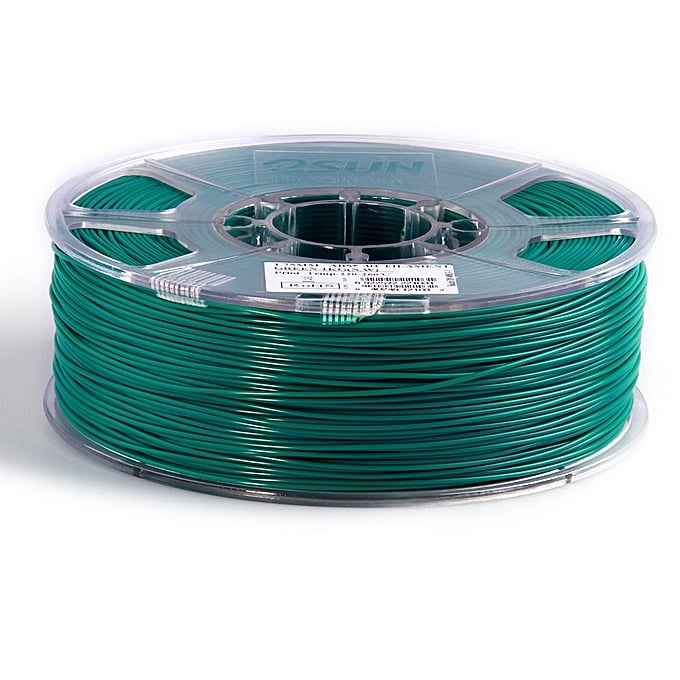

2. PLA 3D Filament

PLA(Poly Lactic Acid) is a special type of thermoplastic made from organic materials, namely cornstarch and sugarcane. The main benefits of PLA are that it is safer and easier to use. Compared to ABS, PLA produces 3D parts which are more aesthetically pleasing. This finish is thanks to its unique sheen and smooth appearance.

The melting point of PLA is much lower than ABS and that makes it weaker. This matters if you are printing moving parts or exposing the parts to high temperatures. Both of these things can result in the 3D objects, cracking, warping or even melting.

PLA print temperature range: 180°C – 230°C (low)

Applications of PLA 3D Filament

PLA has wide-ranging uses. At the professional level, PLA filament uses include medical stitching. We can also see PLA used for various surgical implants, including surgically implanted pins, rods, screws, and mesh. The applications work thanks to the material’s degradable properties. At the amateur level, PLA filament is great for producing a whole range of consumer items. Other benefits of PLA are that it prints faster than ABS, and there’s no need for a heated printer bed. The end products are a decent strength, durable, and offer some degree of impact resistance. Aside from 3D printing, other products that use PLA include food packaging, disposable tableware, and diapers, as a few examples.

Pros and cons of PLA 3D Filament

Pros

- No harmful fumes, produces a sweet aroma when heated

- Easier to work with compared to ABS (great material for beginners)

- Compared to ABS, PLA is less prone to warping

- Available in special effects like glow-in-the-dark colors and translucency

Cons

- Susceptible to clogging the printer nozzle

- Can attract moisture that makes it potentially brittle and more difficult to print

- Less sturdy overall than ABS

3. PET/PETG Filament

Today, PolyEthylene Terephthalate (PET) is a popular 3D material. Another common example of PET is our plastic bottles. This plastic is both stable and harmless, emits no unpleasant or harmful odors and is 100% recyclable. In its raw state, the filament has no color and is crystal clear. Once exposed to cold or heat the material quickly changes to a non-transparent state. A more advanced version if PET is a filament called PETG, also marketed as Amphora AM1800.

PETG print temperature range: 210°C – 230°C

Applications of PET 3D Filament

PET is on a list of FDA approved polymers. This makes it completely ‘food safe’, meaning it’s safe for products like cups, and plates, etc. Needless to say, common applications for PET filament include food containers and various kitchen utensils.

Pros and cons of PET 3D Filament

Pros

- Strong, flexible, and with bio compatibility

- Does not warp

- Does not shrink

- Does not absorb moisture from the air

- Does not degrade in water

- FDA approved, food safe

- Prices for PET are falling

Cons

- Not an easy material for beginners to work with

- Nozzle and printer bed temperatures needs fine-tuning for best results

4. PETT Filament

PETT, whose long name is PolyEthylene Trimethylene Terephthalate is known as a T-Glase filament. Like PET (one ‘T’), it is also a popular 3D printer material that’s food-friendly. The filament is non-biodegradable, though it is a recyclable material.

PETT Print Temperature Range: 210°C – 230°C

Applications of PETT 3D Filament

PETT is another of those FDA-approved polymers. This makes it safe for use with food. The majority of PETT applications are various food containers and other kitchen utensils.

Pros and cons of PETT 3D Filament

Pros

- Strong and flexible

- Bio compatibility

- Does not warp or shrink during the printing process

- Does not absorb moisture or water from surrounding air

- Does not degrade in water

- FDA approved, food safe

- Impressive in bridging

- Prices for PETT falling

Cons

- Difficult material for beginners to work with

- Printer nozzle bed temperature requires fine tuning for best results

5. Nylon Filament

Nylon filament also called as polyamide. This is a synthetic polymer that is stronger and more durable than ABS and PLA and cost-effective. It is also flexible, light, wear-resistant, and less brittle than both ABS and PLA. There are different kinds of nylon filament available.

The difference between them is in the filament’s layer bonding abilities, tensile strength, and water absorption. You can also choose nylon filament that has a translucent or opaque finish and reduced shrinkage.

Nylon print temperature range: 210°C – 250°C (high)

Applications of Nylon Filament

Nylon filament is great to use in a whole variety of applications thanks to its strength, flexible properties, and durability. It’s particularly suited for various consumer products, tools, mechanical components, machine parts, structural parts, containers, and a much more.

Pros and Cons of Nylon Filament

Pros

- Strong, durable and flexible

- Less brittle than ABS and PLA

- 100% thermoplastic material

- Filament can be re-melted and used again without any loss of bonding

Cons

- Needs a high melting temperature

- Breaks down and emits toxic fumes when heated

- Absorbs moisture easily—proper storage is essential

6. PVA Filament

PVA (Polyvinyl alcohol) is a good 3D filament that is typical it is a support material when printing with ABS or PLA. Support materials are necessary when printing 3D parts with notable overhangs. Without the support, these parts would be impossible to print or perfect. As a support material, PVA works best with printers that have duel extruders. All popular desktop FDM printers can use PVA with a heated build platform as this prevents warping during the build process.

PVA print temperature range: 190°C – 220°C (low)

Applications of PVA Filament

In 3D printing, PVA works as a support material (see above). Aside from 3D printing, PVA has many other applications. We can find it used as a thickener in paper adhesives, in personal hygiene products, as a mold-release agent, kid’s putty, and freshwater fishing products, to name a few.

Pros and Cons of PVA Filament

Pros

- A biodegradable, non-toxic material

- Water soluble

- Good durability

- Makes otherwise difficult printing easy

Cons

- Attracts water easily

- Can be difficult to source compared to other materials

- High cost compared to other 3D filaments

7. Sandstone Filament (PLA + Brick)

Sandstone filaments offer a unique finish to your 3D printed parts. This is a PLA material that includes a fine chalk powder to produce a stone-like color and texture. It is also possible to alter the surface characteristics simply by adjusting the printer’s extrusion temperature during the print process. 3D sandstone material is a brick filament offered by various suppliers under different product names. The most well-known right now is Lay Brick.

Sandstone print temperature range: 165°C – 210°C

Applications of Sandstone Filament

The creative use of 3D sandstone filaments has few limits, though it’s fair to say that it has a pretty niche usage. It’s most popular for things like landscapes and architectural display models.

Pros and Cons of Sandstone Filament

Pros

- Unmistakable sandstone appearance and finish

- No heated bed needed to print

- No warping or shrinking during the cooling process

Cons

- Not a particularly durable or flexible material

- Parts can be brittle making them more prone to breaking and snapping

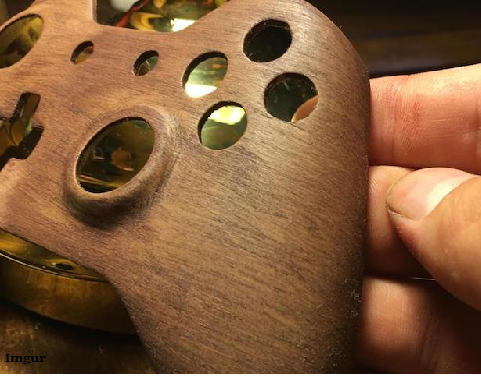

8. Wood Filament

It seems strange, but yes, 3D wood filaments are very real. It’s a great material for anyone who wants or needs to be more creative with their 3D printed projects. These filaments contain a careful mixture of recycled woods with a special binding polymer. The output model not only looks like real wood, it smells like it too. There’s no shortage of impressive examples online that illustrate the amazing finish wood filaments can produce when printed to perfection.

Wood print temperature range: 200°C – 260°C

Applications of Wood Filament

This filament uses for decor, ornate boxes, tables and chairs, figurines, and whatever else catches the imagination.

Pros and Cons of Wood Filament

Pros

- Contains actual wood fibers

- Produces unique wood-like objects in various shades and surfaces

- Higher temperatures will produce darker brown shades

- Altering 3D print temperatures stimulates the growth ring effect of trees

- Allows you to easily work with the finished part to achieve the required finish

Cons

- Weaker, softer material compared to PLA

- Less flexibility and tensile length

- Easily breakable

9. Metal Filament PLA / ABS

Metal filaments are offering some very impressive, unique finishes to 3D printed parts. The materials consist of PLA combined with a higher percentage of fine metallic powders. The 3D printed parts look and feel just as they would if they had been made of 100% metals. Popular choices include aluminum, brass, bronze, copper, and stainless steel. Anyone who wants more of a creative effect can work on the end piece.

Metal print temperature range: 195°C – 220°C (will vary depending on filament)

Applications of Metal Filament PLA / ABS

3D metal filament is perfect for hardware products, jewelry items, statues, replicas of artifacts, and much more. What you print with 3D metals depends a lot on the filaments you choose.

Pros and Cons of Metal Filament PLA / ABS

Pros

- Extremely durable

- Not soluble

- Unique metallic appearance and finish

- Little to no shrinkage while cooling

- No heated print bed needed

Cons

- Not easy to print with for the inexperienced

- Need to fine-tune nozzle temperatures

- Need to regulate flow rate

10. HIPS Filament

High Impact Polystyrene (HIPS) is a bright, white colored 3D biodegradable material. It is safe to use, meaning it has no harmful effects for users who are in close contact with the filament. Like PVA, HIPS also works as great secondary (support) material.

HIPS print temperature range: 230°C – 250°C

Applications of HIPS Filament

For 3D printing, the most common application for HIPS is as a support material for other filaments (see above). Aside from 3D printing, other industries use HIPS because it’s a strong, ridged plastic that they can manipulate to suit their needs. The food industry uses it widely for packaging. Other uses include medicinal trays, signs, all kinds of kid’s toys, and much more.

Pros and Cons of HIPS Filament

Pros

- Acts as an easily removable ABS support material

- When paired with ABS, HIPS is a great dual extrusion support structure

- Non-toxic at close range

Cons

- Some issues with adhesion and curling

- Not easy to work with without a heated bed

11. Magnetic Iron PLA Filament

As the name suggests, magnetic iron PLA filament has magnetic properties. This unique filament is PLA material infused with a powdered iron. These iron particles that give the 3D parts their grainy gunmetal type finish. The objects will also stick to magnets, something that could be useful on various creative projects.

Magnetic iron PLA print temperature range: 195°C – 220°C

Applications of Magnetic Iron PLA Filament

If you want to produce custom made fridge magnets and other such novelties, magnetic iron PLA is used. Magnetic filament is useful for making various DIY projects, sensors, and educational tools, etc.

Pros and Cons of Magnetic Iron PLA Filament

Pros

- Very strong and extremely durable

- Material is not soluble

- Little to no shrinkage during the cooling down process

Cons

- Nozzle temperature needs fine-tuning

- Inflexible

- Heated bed not needed

- Material is expensive compared to other popular filaments

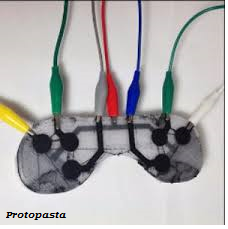

12. Conductive PLA Filament

It is a special type of 3D material that includes a conductive carbon particulate. Without getting too technical, this means the material is able to print low-voltage electrical circuits. These will typically include sensors and light-emitting diodes (LED). When combined with regular PLA filament and a dual-extrusion 3D printer, users can make simple circuit boards direct from the printer’s bed.

Conductive PLA temperature range: 215°C – 230°C

Applications of Conductive PLA Filament

Conductive PLA filament is perfect for open-source electronics platform Arduino projects. If you want to create circuits, LEDs, sensors, and various low-voltage projects, you’ll want explore this filament.

Pros and Cons Conductive PLA Filament

Pros

- Users can produce low-voltage electronic circuits

- Not soluble

- Does not need a heated bed, though a heated bed will produce better results

Cons

- Not very flexible or durable

- Repeated bending may break the material

- Shrinks somewhat during the cooling process

- High cost of filament

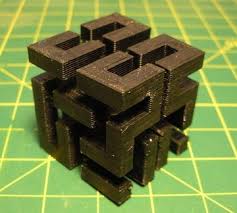

13. Carbon Fiber 3D Printer Filament

The material contains tiny strands of carbon fiber which results in a material that has an excellent structure. It is also rigid and has superior layer adhesion. Carbon Fiber PLA shares similar properties with standard PLA but it’s stiffer. It also offers more dimensional stability, which means warp-free printing.

Carbon fiber print temperature range: 190°C – 230°C

Applications of Carbon Fiber 3D Printer Filament

Carbon fiber PLA filament is a great choice for producing high quality and strong objects. This includes items like protective casings, various mechanical parts, and many other high durability uses.

Pros and Cons of Carbon Fiber 3D Printer Filament

Pros

- Prints quality parts

- Soluble and durable

- No heated bed needed

- Little warping and shrinkage during the cooling process

Cons

- Material contains abrasive strands

- Excessive wear on printer nozzles, especially brass

- Regular users need to invest in harder metals for print nozzles

14. Flexible, TPE Filament

TPE 3D printer filament is super stretchy because of the thermoplastic elastomers. It has such high elasticity properties that it feels like real rubber, easily springing back into shape like an elastic band. TPE is great to use with most FDM 3D printers. If you need to fabricate stretchable 3D parts that can endure more punishment than any regular ABS or PLA, this is your material.

TPE print temperature range: 225°C – 235°C

Applications of TPE Filament

There are wide ranging applications and industries which benefit from TPE filament. We can see it used in household appliances and the automotive sector. It is also a popular for kid’s toys, wearables, and smartphone cases, etc. For commercial use, TPE is found in medical supplies, weather seals for windows and doors, electrical insulation, and the soles of footwear, to name a few.

Pros and Cons of TPE Filament

Pros

- High elasticity properties and exceptional abrasion-resistance

- Smooth consistent diameter

- Bonds well between layers (vital for high-quality)objects)

- Durable material with little shrinkage during the cooling process

- No heated bed needed

Cons

- 3D printing with TPE is difficult for the inexperienced

- Print nozzle needs fine-tuning for optimal performance

- Can extrude from nozzle inconsistently

15. Glow in the Dark Filament

The name needs little introduction as this fun filament does exactly what it glows in the dark. It won’t glow indefinitely though, as the 3D printed object needs exposing to a light source to charge it. Once charged it will emit light in whatever colors you have made your part in. A great use for this material it to decorate children’s bedrooms or to make Halloween themes, and other such creative ideas. It’s a safe, environmentally-friendly filament, making it harmless for everyone to use.

Glow-in-the-dark print temperature range: 180-240 °C

Applications of Glow in the Dark Filament

Imagination drives many of the uses for this fun material. It’s popular for kid’s toys, wearable gadgets, custom phone cases, and many other novelty items. Some creative artists also find it a great medium to work with for artistic designs. Another, more practical use is for light switches as it makes them easy to find in the dark.

Pros and Cons of Glow in the Dark Filament

Pros

- Environmentally friendly, safe to use, biodegradable

- Low shrinkage during the cooling process

- Durable

- No heated bed needed to print

- Similar to regular PLA, which makes printing easy

Cons

- Not food safe

16. Amphora 3D Printer Filament

Amphora is a great filament for anyone who wants to produce objects which are lustrous, bright, and opaque. The Eastman Chemical Company created this fancy material specifically for 3D printing. Most common thermoplastics have uses other than 3D printing technologies, but not this one.

Amphora print temperature range: 220°C – 250°C

Applications of Amphora 3D Printer Filament

Amphora is more of a specialist type of lightweight, impact-resistant, 3D printer filament. Common applications include mechanical parts and other objects that need a material that is of excellent strength, highly flexible, and durable.

Pros and Cons of Amphora 3D Printer Filament

Pros

- No notable odors during the printing process

- Strong material with a high melting point (higher than regular PLA)

- Better layer adhesion resulting in an improved finish

- Impressive performance for bridging gaps

- Little to no warping, cleaner overhangs overall

- FDA-approved, making Amphora food safe

Cons

- Not an easy material to print with

- Printer nozzle and bed need fine tuning for best results

Choosing the Right 3D Printer Filament

This guide gives you a good insight into the different 3D printer filaments on the market. There are others, but the ones listed here are the most widespread, easy-to-source materials at the time of writing. Before you choose the right filament for your next job, you need to check a few boxes. For example, as well as knowing what you intend to build, you also need to understand your printer’s capabilities. Not all 3D printers are able of printing in all 3D materials.

Another consideration is the diameter of the filament, either 1.75mm or 3mm. If you’re unsure, always opt for 1.75mm as it’s easier to work with. 3D filament storage is another crucial area to think about. These plastics can absorb moisture from the air which can mess with the printing process.

And finally, don’t allow the cheapest of the cheap filaments tempt you as they could prove to be a false economy. Seriously, low-cost, low-grade 3D printing filaments are more likely to contain chemical impurities. These impurities can result in unsatisfactory printed parts and clogged-up printer nozzles.

Also, do you know? You can use our affordable online 3D printing service to print 3D models and get them delivered to your doorstep in as little as two days. We offer instant quotations. Click Here to explore more!